Technology Summary

The Invention

Fermilab has developed a way to tune “dressed” cavities by accessing them from the inside— without introducing contaminants or damaging the cavity walls— using specially-designed balloons. A pump fills each balloon with gas until it applies about two bars of pressure— a little less than what’s recommended for standard car tires. This isn’t enough pressure to reshape a cavity cell on its own, but that pressure can be used to influence which cell deforms when forces are applied to the ends of a cavity at room temperature. Balloons allow one to single out a particular cell, either stretching or squeezing it.

If a particular cell needs to be stretched, a balloon inflated inside it provides an extra nudge for it to expand as the flanges are pulled apart. Whereas if a cell needs to be squeezed, a series of balloons can support all the other cells as the two ends are pushed together.

Benefit

Currently, this is the only straightforward way to tune dressed cavities other than cutting the helium vessel to access the outer surface of the cavity cells, tuning the bare cavity, and re-dressing the cavity. This significantly increases the cost and delays the schedule of large-scale particle accelerator projects that comprise hundreds of cavities.

Applications and Industries

The primary application for this technology is the particle accelerator industry, but any industry with components necessitating very specific internal geometries that cannot be easily accessed from the outside could potentially be “tuned” in this way.

Category: Engineering Technologies, Accelerator Technologies

Tags and keywords: Balloon tuning

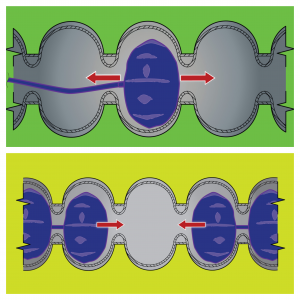

Upper:To stretch one cell of an accelerator cavity, a balloon is placed inside it and inflated.

Lower: To squeeze a particular cavity cell, a balloon is placed inside the cells surrounding it. The balloons support the surrounding cells, resulting in the unoccupied cell being reshaped as forces are applied to each end of the cavity.

Invention Details

Patent Status: Patented

Contact:

Aaron G Sauers, CLP

630-840-4432

asauers@fnal.gov

Fermilab, MS 312 – PO Box 500

Batavia, IL 60510