Technology Summary

Electron beam additive manufacturing is a rapidly growing industry. Electron guns capable of reaching higher energies and higher average power can enable larger melt pools, higher production speed, and permit broader range of materials for metal additive applications. Such electron guns require technologies beyond those normally achieved with DC high voltage sources. As an example, superconducting radio frequency (SRF) technology is an option to achieve higher energy and higher power with excellent efficiency. However, current SRF technology requires complex cryogenic systems to safely handle cryogenics gases or liquids such as Helium. Such complexity severely restricts their usage to R&D facilities.

The Invention

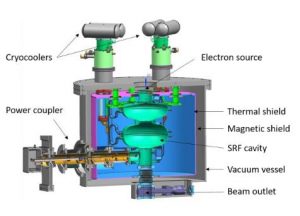

Fermilab has developed a high power, high energy superconducting radio-frequency electron gun for advanced metal additive manufacturing applications. The novel design is based on a technique that eliminates liquid Helium entirely and dramatically reduces the complexity of the system.

Benefit

- Enables printing of high performance alloys such as tungsten, niobium, and high entropy alloys

- 15X larger print sizes or, alternatively, 15X faster processing times

- Higher power and decreased spot size

- More precise tolerances

- In situ SEM-like capabilities for defect detection

Applications and Industries

- Rapid prototyping

- Medical

- Aerospace

- Automotive

Category: Engineering Technologies, Accelerator Technologies

Tags and keywords: Additive manufacturing, 3D printing

Invention Details

Patent Status: Patent-pending

Contact:

Aaron G Sauers, CLP

630-840-4432

asauers@fnal.gov

Fermilab, MS 312 – PO Box 500

Batavia, IL 60510