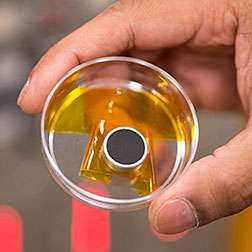

Nanocathode

Scientists are a step closer to building an intense electron beam source without a laser. Using DOE’s High-Brightness Electron Source Lab, a team led by scientist Luigi Faillace of RadiaBeam Technologies is testing a carbon nanotube cathode—about the size of a nickel—that completely eliminates the need for a room-sized laser system. Tests with the nanotube cathode have produced beam currents a thousand to a million times greater than the one generated with a large, pricey laser system.

The technology has extensive applications in medical equipment and national security, since an electron beam is a critical component in generating X-rays. While carbon nanotube cathodes have been studied extensively in academia, Fermilab is the first facility to test the technology within a full-scale setting.

Fermilab was sought out to test the experimental cathode because of its capability and expertise for handling intense electron beams, one of relatively few labs that can support this project. A U.S. Department of Energy Small Business Innovation Research grant funds the RadiaBeam-Fermilab collaboration.

The new cathode appears at first glance like a smooth black button, but at the nanoscale it resembles, in Piot’s words, “millions of lightning rods.” When a strong electric field is applied, it pulls streams of electrons off the surface of the cathode, creating the electron beam. The exceptional strength of carbon nanotubes prevents the cathode from being destroyed. Traditionally, accelerator scientists use lasers to strike cathodes in order to eject electrons through photoemission. The electric and magnetic fields of the particle accelerator then organize the electrons into a beam. The tested nanotube cathode requires no laser: it only needs the electric field already generated by an accelerator to siphon the electrons off, a process dubbed field emission.